When we think about efficiency in mechanical or industrial systems, our minds often jump straight to the big machines—the pumps, motors, or turbines that power the entire setup. But behind the scenes, it’s often the smaller components that quietly determine whether a system runs smoothly, economically, and reliably. These small parts may not grab attention, but they are the unsung heroes that keep everything in balance.

Why Small Components Matter

Imagine a large industrial cooling system. The chiller, pipes, and control panels are all impressive in size and cost. But what happens if a small connector leaks, or a valve fails to regulate flow properly? Suddenly, the entire system suffers inefficiencies, energy waste, and potentially costly downtime.

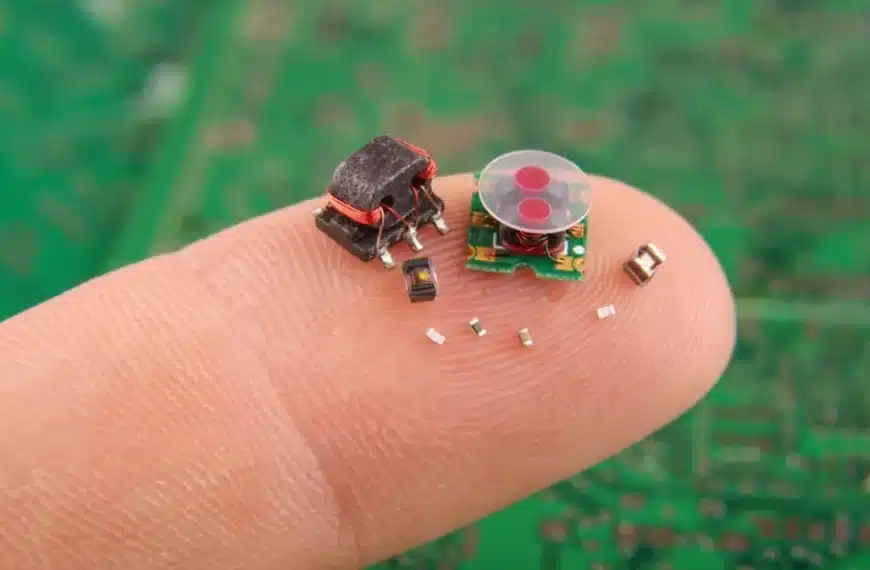

This is the reality in almost every field—HVAC, manufacturing, automotive, or even household appliances. The efficiency of the whole often depends on the reliability of the smallest details. Components like valves, fittings, seals, and sensors may look minor, but they play critical roles in precision, safety, and energy savings.

Precision Control: The Hidden Key to Efficiency

System efficiency doesn’t just come from raw power; it comes from control. A machine that can adjust its flow, pressure, or temperature with precision uses far less energy than one that runs at full force all the time. This is where small components step in.

Take valves, for example. They regulate the direction and pressure of fluids or gases, ensuring only the necessary amount is delivered. Without them, systems would waste energy and wear out faster. Similarly, tiny sensors provide real-time feedback to optimize operations, while seals and gaskets prevent leaks that would otherwise lead to losses.

The Role of Specialized Valves

Among small components, valves deserve a special mention because of their widespread use. They might sit quietly inside pipelines, but their function is anything but small. By opening, closing, or partially restricting flow, valves directly impact efficiency.

For instance, a brass solenoid valve is often used in water, air, or oil systems where durability and reliability are critical. Brass offers excellent corrosion resistance, while the solenoid mechanism allows for automatic, precise control. In applications ranging from irrigation systems to industrial automation, this single component can mean the difference between smooth operation and costly inefficiency.

Real-World Examples

- HVAC Systems: A single faulty valve can cause uneven airflow, leading to energy waste and uncomfortable environments.

- Manufacturing Plants: Precision valves and sensors ensure materials are processed at the right pressure and temperature, reducing waste.

- Automotive Systems: Tiny components like injectors and solenoid valves regulate fuel flow, directly affecting fuel efficiency and emissions.

- Home Appliances: Washing machines, dishwashers, and coffee makers all rely on small valves and connectors to deliver consistent results.

In each case, efficiency depends on components that might cost only a fraction of the total system but influence its performance dramatically.

Maintenance and Reliability

Another reason small components are vital is their role in maintenance. A major machine breakdown often traces back to the failure of a minor part. Regular checks on valves, fittings, and seals can prevent problems before they escalate. Investing in high-quality components upfront also reduces the risk of breakdowns, saving both time and money in the long run.

Looking Ahead

As industries push for smarter, more sustainable operations, the importance of these smaller components will only grow. With systems becoming increasingly automated, precision parts like solenoid valves and sensors will play a central role in balancing efficiency with reliability. Even as technology advances, the principle remains the same: small parts make big differences.

Conclusion

Efficiency doesn’t just come from the machines we see towering on factory floors or humming in our buildings. More often than not, it comes from the small, often unnoticed components that regulate, protect, and optimize those systems. A single valve, connector, or sensor can have an outsized impact on performance, proving that in engineering, no part is ever truly “small.”

By giving these components the attention they deserve, industries can unlock higher efficiency, greater reliability, and more sustainable operations—all thanks to the smallest building blocks of their systems.