High precision turning is crucial for producing ultra-accurate components with micron-level tolerances, essential in industries like aerospace, medical devices, and electronics. This article explores its principles, applications, technologies, and future trends.

Understanding High Precision Turning

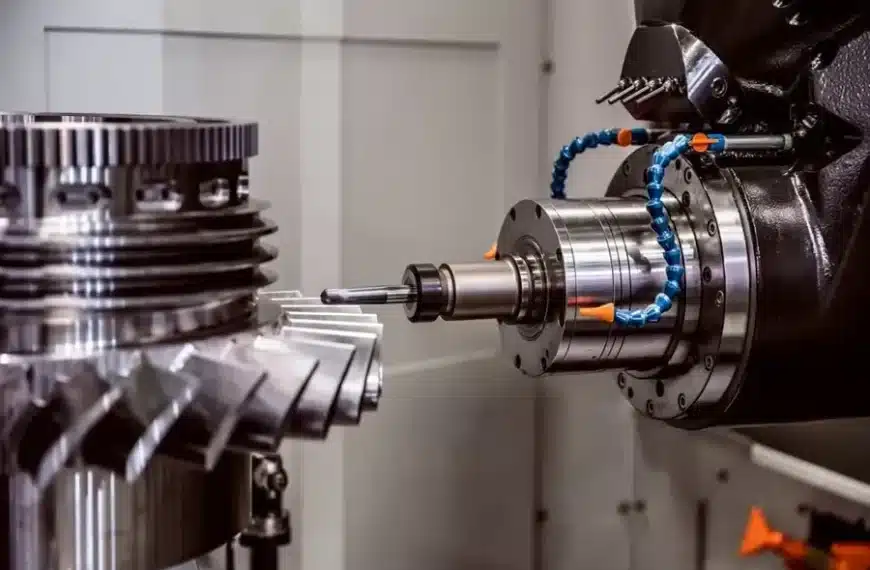

High precision turning is an advanced form of traditional turning, a machining process where a cutting tool removes material from a rotating workpiece to create a cylindrical shape. What sets high precision turning apart is its exceptional level of accuracy and the fine surface finishes it can achieve.

Conventional vs. High Precision Turning

While conventional turning is suitable for many applications, it typically operates with tolerances in the range of hundredths of a millimeter. High precision turning, on the other hand, pushes the boundaries of accuracy to the micron or even sub-micron level. This leap in precision is made possible by several key factors:

- Machine Tools: High precision turning relies on state-of-the-art lathes that are built for rigidity, thermal stability, and minimal vibration. These machines often feature high-resolution feedback systems and advanced motion control to ensure precise tool positioning.

- Cutting Tools: The tools used are made from ultra-hard materials and have highly specific geometries to ensure clean cuts and minimize tool wear.

- Workholding: Securely and accurately holding the workpiece is critical. High-precision chucks and collets are used to minimize runout and ensure the part rotates perfectly on its axis.

- Process Control: The entire process is meticulously monitored and controlled, often in real-time, to maintain consistent quality.

The role of Computer Numerical Control (CNC) machines is central to achieving this level of accuracy. Advanced CNC systems can execute complex tool paths with incredible speed and repeatability, translating digital designs into physical parts with minimal deviation. This includes specialized equipment like CNC Swiss Screw Machining centers, which are ideal for producing small, complex parts with tight tolerances.

Materials and Tooling

The success of high precision turning depends heavily on the right combination of workpiece materials and cutting tools.

Suitable Materials

Not all materials are created equal when it comes to precision machining. The ideal material should have consistent properties and good machinability. Common materials used in high precision turning include:

- Aluminum Alloys: Lightweight and easy to machine, aluminum is often used for aerospace and electronics components.

- Stainless Steel: Known for its strength and corrosion resistance, it is a staple in medical and food-grade applications.

- Titanium: Prized for its high strength-to-weight ratio and biocompatibility, titanium is essential for medical implants and high-performance aerospace parts.

- Plastics and Polymers: Specialty plastics are used for their unique properties, such as chemical resistance and electrical insulation.

Cutting Tool Selection

The cutting tool is the point of contact where the magic happens. The choice of tool material and geometry is critical for achieving the desired surface finish and dimensional accuracy.

- Tool Materials: Carbide is a versatile and widely used material, but for the highest precision and when machining hard materials, Polycrystalline Diamond (PCD) or Cubic Boron Nitride (CBN) tools are often required.

- Tool Geometry: The shape of the cutting edge, including the rake and clearance angles, must be optimized for the specific material being cut to reduce cutting forces and heat generation. Proper tool maintenance, including regular inspection and replacement, is essential to prevent degradation in part quality.

Process Control and Optimization

Maintaining micron-level accuracy requires a tightly controlled manufacturing environment. Even small variations in conditions can have a significant impact on the final product.

Temperature and Vibration Control

Thermal expansion is a major challenge in precision machining. As the machine and workpiece heat up during operation, they can expand, leading to dimensional inaccuracies. To combat this, high precision facilities often employ climate control systems to maintain a stable ambient temperature. The machines themselves may have internal cooling systems to regulate the temperature of key components like the spindle and motors.

Vibration is another enemy of precision. It can be caused by the machine itself, external sources, or the cutting process. High precision machines are designed with massive, rigid bases and vibration-damping features. They are often installed on isolated foundations to shield them from floor vibrations.

Monitoring and Adjustments

Modern CNC machines are equipped with sensors that monitor cutting forces, tool wear, and part dimensions in real time. This data can be used to automatically adjust cutting parameters, such as speed and feed rate, to optimize the process and compensate for any deviations. The use of coolants and lubrication is also crucial. They help to manage heat, reduce friction, and flush away chips from the cutting zone, all of which contribute to a better surface finish and longer tool life.

Applications in Various Industries

The capabilities of high precision turning have enabled breakthroughs in numerous fields.

- Aerospace: Jet engine components, guidance system parts, and structural fasteners require extreme precision to ensure safety and performance under demanding conditions.

- Medical Devices: The medical industry relies on precision turning for surgical instruments, orthopedic implants (like hip and knee joints), and tiny components for pacemakers and other implantable devices.

- Electronics: As devices get smaller, the need for miniature connectors, sensor housings, and other intricate parts has grown. High precision turning makes it possible to produce these components at scale.

- Automotive: In the automotive world, precision is key for high-performance engine parts, fuel injection components, and sensors that are critical for efficiency and safety.

Challenges and Solutions

Achieving micron-level accuracy is not without its difficulties. Common challenges include:

- Tool Wear: As cutting tools wear down, the dimensions and surface finish of the parts can change. The solution is to use durable tool materials, apply optimized cutting parameters, and implement a proactive tool replacement schedule.

- Thermal Expansion: As discussed, temperature fluctuations can cause materials to expand or contract. This is managed through strict environmental control and machine cooling systems.

- Vibration: Unwanted vibrations can lead to poor surface finishes and inaccuracies. This is addressed through rigid machine design, vibration damping, and proper balancing of rotating components.

The Road Ahead

The field of high precision turning is constantly evolving. Future trends point towards even greater accuracy and automation. Advancements in machine technology, such as direct-drive motors and hydrostatic guideways, promise to reduce vibration and improve motion control further.

Artificial intelligence (AI) and machine learning are also beginning to play a significant role. These technologies can analyze vast amounts of process data to predict tool wear, optimize cutting parameters, and even detect potential issues before they occur. This will lead to more intelligent, self-correcting manufacturing processes that can operate with minimal human intervention.

Conclusion

High precision turning is a key technology driving innovation in advanced industries. By enabling greater accuracy and miniaturization, it helps create more efficient, reliable, and capable products. Precision and attention to detail remain essential for shaping the future.